Application of control system in wool planter industry

Brushes: Utensils made of wool, brown, plastic wire, metal wire, etc. for removing dirt or smearing ointment, etc. Generally long or oval, some with a handle. Brushes are also known as brushes. Brushes are classified into civil brushes and industrial brushes according to their trial areas.

The brushes in daily life mainly include kitchen brushes, bath brushes, shoe brushes, toothbrushes, pot brushes, laundry brushes, stainless steel sanitary brushes, toilet brushes, wall brushes, paint brushes, etc. In industrial production, the main functions are dust control, polishing, cleaning and grinding. Such as all kinds of vegetable cutter brushes, all kinds of stereotyping machine brush wheels, comber brushes, grinder brushes, brown brushes, all kinds of road sweeper brushes, cleaning machine brushes, edge grinder brushes, golden finger grinding wheel, felt type brush rollers, etc. Our life is inseparable from the use of brush products. The market demand for brushes is large and there are many kinds of brushes. It has a huge market development prospect, but also puts forward high requirements for wool planting machine processing technology and processing efficiency.

As a leading supplier of control system and overall solution for wool planting drilling machine in China, Taifenglai is a large-scale domestic enterprise engaged in research, development, production and service of automatic brushing equipment. Has many years of brushing machinery production experience, has a high-quality technical team.

Our factory adheres to the business philosophy of "Quality Foundry Brand, Word of mouth is the best marketing method", and meets the requirements of our customers with high quality products and perfect and fast service. Variety, stock, affordable price, timely delivery.

Brief introduction of drilling wool planter:

The wool planting/drilling machine can be used to produce various brushes for daily use and industry, such as toothbrush, broom, shoe brush, wooden brush, wire brush, toilet brush, etc.

According to the number of axes, it can be divided into two axes, three axes and more than four axes. According to the function, it can be divided into wool planting machine, drilling machine and drilling and planting machine.

At present, two-axis and three-axis machines are commonly used. Because most products only need two or three axes, machines with more than four axes are used to produce some special-shaped brushes.

High-speed toothbrush machine is also a kind of wool planter, because its process has some special features, and as a separate category.

At present, high-end five-axis and five-head wool planting/drilling machine equipments, with high-speed, multi-station simultaneous drilling and planting, all kinds of special-shaped brush processing, self-programming, good performance but expensive, are monopolized by foreign manufacturers.

Successful application of typical wool planter machine:

Control system requirements for wool planting/drilling machine:

At present, the speed requirement of wool planting/drilling machine is generally 500-1000 holes/min. It can memorize 100-2000 kinds of processing graphics files and input up to 1000-100,000 holes. Supporting the function of U disk, it can easily and quickly realize the copy of processing documents between different processing machines. Support handheld box manipulation, etc. It has the function of password protection.

The wool planter adopts two kinds of processing data manipulation modes, i. E. teaching and editing. With an intuitive display system of processing conditions, users can quickly know the processing process and adjust it at any time. With the functions of adding, modifying, inserting and deleting processing data, it can solve the problems of hole offset, porous and leaky easily and quickly.

For some regular graphics, such as a row of neat holes, the spacing is equal, or one part is the same as the other part, just different location, then some special functions can be used to quickly generate the required data. These functions include perforation, replication, translation and the innate nature of common patterns.

Through the hole-dividing function, fast and regular pattern of hair-planting drilling can be obtained. The duplication function supports the duplication of the whole processing hole position and part of the processing hole position. It does not need to re-import the processing data, and has the translation function. It can correctly translate and process the whole hole position of the product's wool planting hole. It does not need to modify the data manually anymore. It is simple and fast to operate.

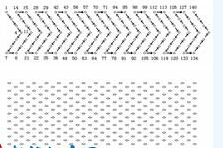

Commonly used patterns are innate, such as square hole, plum blossom hole, herringbone hole, elliptical hole and so on, which need to input several specific parameters and can be born with the whole processing data of wool planting. As follows:

In terms of mode of operation, it has automatic processing, semi-automatic processing, full hole processing, hole filling processing, single step processing and single step back processing. Simulated processing function. The above processing methods can also be cross-configured according to needs.

Support automatic flapping function, support monochrome and bichrome wool planting, can drill wool planting, drilling, wool planting processing mode switching.

It can modify or specify the initial hole position of hair planting. When the distance between the hole and the processing hole is long, it can reduce the spindle speed and restore the normal spindle processing speed after the platform is in place. It can also stop the spindle to a high position and wait for the platform to be in place and restore the normal spindle processing speed. High stop function is adopted when changing color.

It has a rich set of machine processing parameters such as processing speed, teaching speed, back-to-origin speed and jump interval for each axis. The automatic detection and alarm function in the process of processing enables users to quickly find and solve problems and prevent accidents such as heavy hair alarm, servo alarm, brush alarm, air pressure alarm, aluminum wire alarm, material shortage alarm, etc. With diagnostic function, it can detect input and output signals, and help users easily troubleshoot.

Exhibition of processed products:

Concluding remarks:

Through the long-term use of customers, Zhongweixing wool planting/drilling machine control system is highly praised in the aspects of stability, comprehensiveness of functions, convenience of operation and so on. The development and application of high-end five-axis and five-head wool planting/drilling machine control system breaks the monopoly position of foreign manufacturers. With the rapid improvement of the production capacity of domestic wool planting/drilling machine industry, the market of wool planting machine becomes more competitive. With an efficient, stable and fully functional wool planting/drilling machine control system, no doubt it can gain the upper hand in the fierce competition of wool planting/drilling machine market.

-

08-07

Introduction of PCB Grinding Brush Roller

The grinding brush rollers used in PCB manufacturing process can be divided into two categories according to their functions: grinding brush rollers and cleaning brush rollers, while grinding brush ro

-

08-07

How to Solve the Problem of Industrial Brush Hair Falling Always

Brush bristles often fall when toothbrush planter uses industrial brush. There are two main reasons for brush bristles falling. One is the quality of brush itself. The brush bristles fall a lot before

-

08-07

Why do wool planter fabrics sell well?

As the climate gradually cooled, wool planter fabrics came to the peak season, there are everywhere on the market. The wool planter fabric is based on various kinds of cloth, on which nylon or viscose

-

08-07

Reasons for poor finished products of wool planter

Top: Simple Bending of Copper Wire1. Partial Wear and Replacement of Cut Copper Head2. Wear Replacement of Cutting Copper Knife3. Improper adjustment of wool planting head and copper cutting knife fro